Anaerobic System Design and Technology

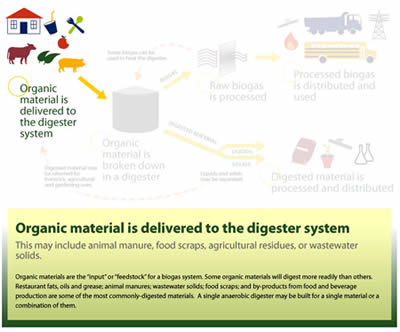

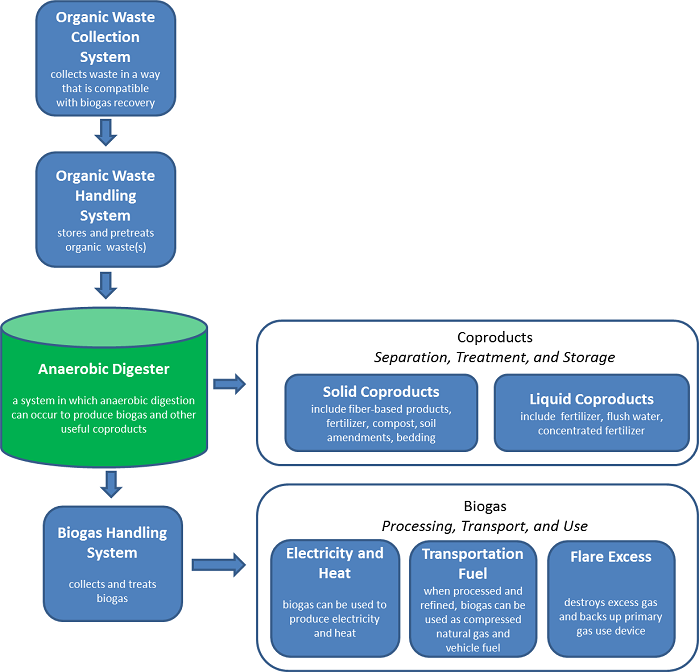

There are several process steps that can be used alone or in combination to treat and manage manure. The following diagram illustrates the elements of a biogas recovery system. Details about each element are provided below the diagram.

Organic Waste Collection System

Manure is collected and placed in a centralized location in a way that is compatible with biogas recovery. Co-digestion feedstocks, such as food processing waste and food scraps, are delivered to the facility where it is prepared for processing.

Biogas production is best suited for farms that collect manure:

- As a liquid, slurry or semi-solid;

- At a single point (a lagoon, pit, pond, tank or other similar structure);

- Every day or every other day;

- Free of large amounts of bedding or other materials (e.g., rocks, stones, straw or sand), which can clog the pipes of the digester and hinder operation.

Other materials such as feed additives with antibiotics and equipment cleaning and maintenance compounds (e.g., detergents, acids and halogens, etc.) may be harmful to anaerobic bacterial action. The typical use of these materials has not been a problem in full scale digesters. However, threshold levels for these compounds have not been established, so operators should be careful not to release large quantities of these materials into manure before it is fed to the digester.

Organic Waste Handling System

The waste handling system prepares the feedstock for use in the anaerobic digester. Depending on the type of feedstock and the type of digester, pretreatment may be required. Pretreatment steps may include:

- Size reduction: Depending on the type of AD/biogas system, the incoming feedstock may need to undergo size reduction. This is usually the case with continuously mixed low solid systems requiring a homogenized feedstock that is easily pumpable and mixed into the reactor.

- Contamination removal: Depending on the feedstock’s source, contaminants such as sand or packaging can show up at the facility. Prior to digestion, they need to be removed because they can disrupt the AD system over time. There are many available preprocessing options that can remove sand (sand separators, hydro-cyclones, or sand settling lanes), plastic bags, and other non-digestible materials (trommel screens or hydro-pulpers). Materials separated as contaminants are usually sent for disposal at a landfill.

- Equilibration and Storage: The final blended feedstock is temporarily stored before being introduced into the reactor. Storage prior to digestion equilibrates and homogenizes the material and evens out fluctuations in the amount and other characteristics of the feedstock. Depending on the size and temperature of the equalization and storage vessel, hydrolysis and acidogenesis can begin leading to significant odors.

Anaerobic Digester Designs

Once the feedstock is collected and prepared, it is introduced to the anaerobic digester, which is sometimes referred to as an anaerobic reactor. Given the specific type of manure collection system, the digester is designed to provide the optimal conditions for converting the organic waste into biogas.

Covered Lagoon

In a covered anaerobic lagoon design, methane is recovered and piped to the combustion device from a lagoon with a flexible cover. Some systems use a single cell for combined digestion and storage.

Plug Flow

Plug flow digesters are primarily used at dairy operations that collect manure by scraping. Mixed plug flow systems have been used at a wider variety of operations because they can tolerate a broader range of solids concentrations.

Complete Mix

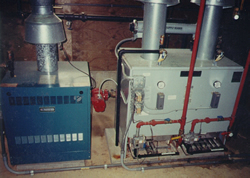

Complete mix digesters are designed with an enclosed, heated tank with a mechanical, hydraulic or gas mixing system. Complete mix digesters work best when there is some dilution of the excreted manure with water (e.g., milking center wastewater).

Other Designs

Other common designs for anaerobic digesters include:

- A batch digester is the simplest form of digestion, where manure is added to the reactor at the beginning of the process in a batch and the reactor remains closed for the duration of the process.

- Induced Blanket Reactors are digesters in which a blanket of sludge develops and retains anaerobic bacteria, providing a bacteria-rich environment through which the feedstock must pass.

- Fixed film digesters contain plastic media (e.g., pellets) on which bacteria attach and grow, instead of relying solely on suspended bacteria to break down the digester feedstock.

Coproducts: Solid and Liquid Components

Digested solids (known as fiber for farm-based systems) can be removed from the digester effluent with a solids separator. All manures produce recoverable solid fiber that may be used as animal bedding, as a soil amendment, a primary constituent in potting soils, or bio-based products (e.g., bioplastics). Emerging applications for effluent solids include use in structural building materials, such as deck boards and particle board.

The liquid effluent from a digester can be used as a fertilizer, reducing the purchase of commercial fertilizers.

Biogas Handling System

Captured biogas is transported through a pipe from the digester, directly to a gas use device or to a gas treatment system. In most cases, the only treatment needed is to remove excess moisture prior to combustion. However, if the feedstock contains high concentrations of sulfur, then hydrogen sulfide is removed from the gas to prevent corrosion of the combustion device. Temporary biogas storage may be needed to help balance production with demand, utilization system capacity, and/or end user needs.

Biogas: Processing, Transport, and Use

Electricity and Heat

While a variety of biogas use options are available, the collected biogas is most often used to generate electricity.

Thermal energy in the form of waste heat, produced during electricity generation, can be recovered to heat digesters or adjacent buildings.

Biogas can be fired directly in boilers or heaters as a replacement for propane.

Transportation Fuel

Biogas can be processed to pipeline quality and sold to the local gas utility.

Biogas can be converted to compressed natural gas (CNG) which can be used in applications such as vehicle fuel.

Flare Excess

Flares are used to combust excess biogas or to combust biogas during periods when the primary gas use device is undergoing maintenance or repair. In cases where the primary purpose of the digester is to control odor or generate carbon credits, all of the biogas may be flared.

Learn More

Learn more from the following resources: