Microwave Drying Apparatus for the Minimization of Drinking Water Plant Residuals

Inventors: Darren A. Lytle, Mallikarjuna N. Nadagouda

Owned by EPA

Patent Information (Justia Patents)

Federal Technology Transfer Act (FTTA) staff: Contact us if you are interested in learning more about how to license this technology.

Summary of the Technology

This invention is a method and apparatus that affordably and quickly reduces the amount of and/or treats residuals from a processing plant. A method is provided for treating residuals or waste streams from a drinking water treatment plant which may contain plant residuals or waste streams and irradiating both plant residuals and waste streams with microwave radiation. This method also dries the plant residuals to a desired moisture, weight, and reduces the volume of the waste.

Background

Typically, drinking water treatment (DWT) plants receive water directly from a water source, e.g., river, lake, reservoir, or wells, or a secondary supplier. The DWT plants then process or treat the received water before providing potable water to its customers or consumers. Water treatment operations can include filtration, precipitative softening, membrane separation, ion exchange, activated carbon filtering, disinfection, chlorination, sedimentation, and coagulation. During the water processing or treatment, the DWT plants treat the water and remove contaminants that are unhealthy or undesirable for consumption, which becomes waste streams or plant residuals. For example, such contaminants include aluminum, copper, lead, nitrates, barium, radium, selenite, ammonia, arsenic, cadmium, zinc, phosphorus, iron, manganese, potassium, and salts thereof, oil and grease, biochemical oxygen demand (BOD). Treating these waste stream by the conventional method is costly and requires considerable additional infrastructure. The Microwave Drying Approach addresses these issues.

How the Technology is Different

Microwave radiation is an efficient, environmentally friendly and economically viable heating method for many applications. Microwave technology is emerging as an alternative energy source powerful enough to accomplish chemical transformations in minutes, instead of hours or days. Consequently, microwave radiation is presently seeing an exponential increase in acceptance as a technique for enhancing chemical synthesis.

The microwave radiation device:

- Is more effective and environmentally friendly – Currently, drinking water treatment plants use conventional energy resources such as coal and oil, while microwave radiation benefits both the economy and the environment. The microwave processing vessel can also prevent overexposure to microwave radiation to the environment by metal mesh screens, cages, or other structures to prevent radiation from escaping.

- Is faster and more efficient – Microwave drying reduces the volume, weight, and moisture content of the drinking water treatment plant residuals. In addition, more processing vessels can be used, where plant residuals or waste are dried and/or treated in iterative steps.

- Can be used alongside ceramic materials – It was found that the use of ceramic materials accelerated the drying process. The ceramic material reflected the microwave radiation and radiant heat from the microwave source and continually heated plant residuals. This allows for an accelerated heating process during microwave irradiation.

- Allows for transport of plant residuals – After the irradiating and the drying is complete, plant residuals can be exposed in landfills, land application, or deep well injection.

Additional Advantages

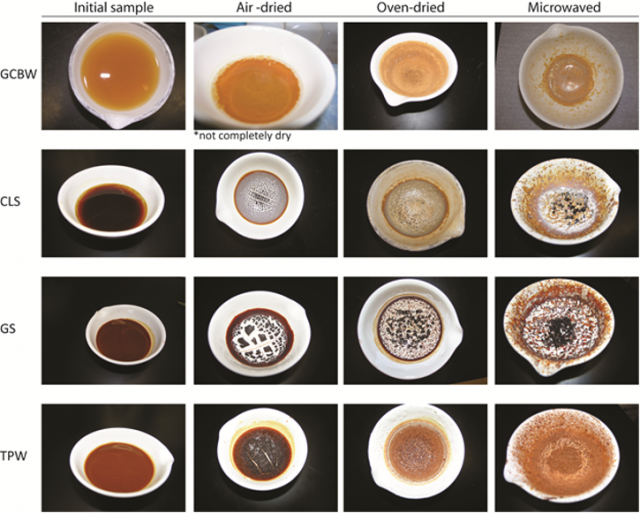

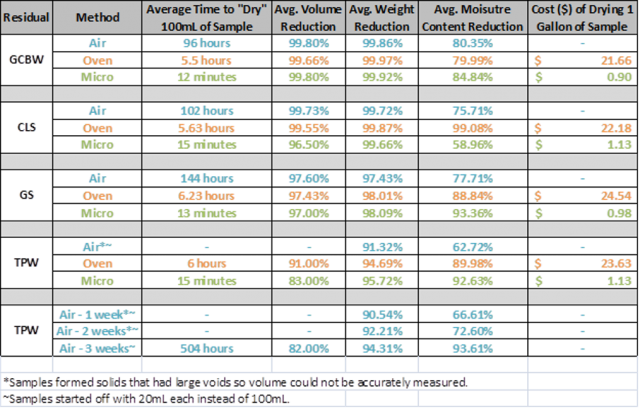

In a study comparing the drying processes by air, conventional ovens, and microwave radiation device techniques, it was found that the microwave device:

- Significantly reduced drying time demonstrated at bench-scale with effective water removal/volume reduction

- Improved overall efficiency and capacity for plant residual or waste treatment over conventional drying methods.

- Had higher processing speeds, with faster start-up and shutdown.

- Better quality and quality control versus time.

- Reduced fire, explosion, toxic hazards, to have safer operations.

- Reduced volatilization of hazardous constituents through improved temperature control.

- Reduced environmental impact, for better sustainability

- Reduced volume, which translates to lower costs for transport and waste disposal.

Although the microwave method did not always produce the lowest volume reduction percentage compared to conventional drying and air drying, it was determined to be an advantage over the conventional drying methods due to its volume, weight, and moisture content reduction and time for drying.