Groundwater Monitoring of Polychlorinated Biphenyls: Filtered vs. Unfiltered Sampling

March 2024

On this page:

- PCBs in Groundwater

- Turbidity in Groundwater

- Groundwater Well Development

- Options for Addressing Turbidity in a Groundwater Sample

- Additional Reference

The purpose of this webpage is to provide information on groundwater sampling results about filtered versus unfiltered samples tested for PCBs. The intended audience is environmental professionals familiar with groundwater sampling.

PCBs in Groundwater

Generally, PCBs are hydrophobic and do not like mixing with water. So, PCBs are more typically found in soil rather than groundwater. However, PCB contamination may be present in groundwater because of facilitated transport associated with solvents, emulsions, or other colloids.

EPA evaluates groundwater contamination based on unfiltered samples as filtering can remove some of the content in the sample and may provide inaccurate results. Both filtered and unfiltered samples might be presented in a report, but unfiltered samples capture undissolved contaminants needed for the determination of regulatory status. So, it’s important that factors such as sampling techniques and turbidity be evaluated to eliminate the need to filter the sample.

Turbidity in Groundwater

Turbidity is the measure of relative clarity of a liquid. It is an optical characteristic of water, measured as the amount of light scattered by material in the water when a light is shined through the water sample. The higher the amount of scattered light, the higher the turbidity, representing cloudier water with more particles throughout. The measurement of turbidity is a key test of both water clarity and water quality. Turbidity in groundwater samples is measured in nephelometric turbidity units. The lower the NTUs, the clearer the water. Turbidity in groundwater samples is caused by aquifer solids (e.g., sand, silt, clay) suspended in the water, which can cause unintended sampling of the sediment instead of the groundwater. Turbidity in groundwater sampling is minimized by proper well development (discussed below) and low flow sampling techniques.

Groundwater Well Development

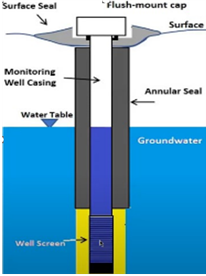

For chemical waste landfills, the TSCA PCB regulations require that all groundwater monitoring wells be cased, and that the annular space between the monitoring zone (zone of saturation) and the surface be completely backfilled with Portland cement or an equivalent material to effectively prevent percolation of surface water into the well bore. The well opening at the surface needs a removable cap to provide access and prevent entrance of rainfall or stormwater runoff. The well needs to be pumped to remove the volume of liquid initially contained in the well before obtaining a sample for analysis. The discharge should be treated to meet applicable state or federal discharge standards or recycled to the chemical waste landfill (Title 40, Code of Federal Regulations, Section 761.75(b)(6)(ii)). If PCB groundwater monitoring is required at other sites, similar conditions may apply.

One of the major goals of well development is to produce a well capable of consistently yielding groundwater samples of acceptably low turbidity. Groundwater samples with excess turbidity may contain PCBs sorbed onto soil particles, which can alter water quality and result in erroneous chemical analysis. Proper well development creates a graded filter pack around the well screen by pumping out the finer grained particles from the filter pack. When pumping is first initiated, natural materials in a wide range of grain sizes are drawn into the well, producing very turbid water. As well development continues, the natural materials are retained by the filter pack, producing progressively thinner layers of coarse particles against the well screen until an effective graded filter is produced, minimizing turbidity. Prior to collecting a sample, turbidity readings should be taken while purging the well, not later at a laboratory. The point of the purging and stabilization process is to get a low flow sample with the lowest amount of turbidity possible and to stabilize other water quality parameters (e.g., pH, temperature, conductivity, redox potential). The well should be sampled with as little interruption in pumping and flow rate as possible, to avoid causing disturbances that may result in higher turbidity.

Options for Addressing Turbidity in a Groundwater Sample

In addition to proper well development, turbidity meters should be calibrated prior to sampling. Turbidity meters are optical-light transmission tools, and keeping the sensor and sample container clean is crucial. If turbidity or other parameters are an issue in the groundwater samples (i.e., turbidity >10 NTUs), further well development or well replacement may be needed. If well replacement is needed, the well should be installed with a properly designed sand pack grain size and slot size for the well screen. Consult with your Regional PCB Coordinator to identify the appropriate course of action (i.e., well placement or alternative method of purging or alternative casing).

If the reconditioned wells continue to produce samples with unacceptable turbidity, samples should still be analyzed unfiltered. A duplicate sample may be taken and filtered with a 2-micron filter. However, the EPA bases its regulatory decisions on unfiltered samples using the appropriate method, unless otherwise approved by the EPA. When requesting consideration of an alternate approach, justification should be provided to assist in the EPA’s decision.

Additional References

Disclaimer: The recommendations on this webpage do not impose legally binding requirements and will not be implemented as binding in practice. They do not impose any obligations on private parties, nor are they intended to direct the activities of any other federal, state, or local agency or to limit the exercise of their legal authority.